poultry farm equipment

Automatic Broiler Cages

A:Cage Frame

Material:Q235 high quality Steel material from brand manufacturer:275g/m2 Hot-dip Galvanized Steel,stronger equipment with better corrosion resistance.

B:Automatic Birds harvesting system:automatic transport broilers out of the house,daily manure removal to reduce ammonia emissions in the house to minimum.

C:Plastic Slat Floor: pull type soft pp floors,prevents breast blisters and promotes clean and healthy feet thus providing excellent hygienic,quick and efficient moving out of broiler

D:4 tiers battery cage:2-4 times higher capacity compared to floor system,high utilization of space ,reduced energy costs for heating or cooling.

A1.Automatic transport of broilers out of house.

A2.Daily manure removal.

A3.Simple cleaning and disinfection after the batch.

A4.Survival rate up to 99.8%.

A5.Higher uniformity of marketing weight.

A6.Dimensions:3000*1800mm,3 tiers,4 tiers.

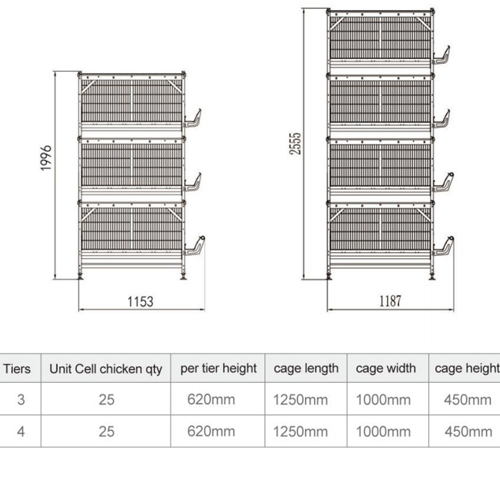

Manual Broiler cages

Focusing on the large-scale breeding needs of modern broilers,to meet the characteristics of fast and safe production of broilers develop unique cages and systems for feeding drinking,manure removal,and environmental control,based on the healthy growth environment of broilers and help customers achieve economic benefits

M1.Fully assembled and high accuracy installation for easy maintenance.

M2.Double portal structure for more convenient feeding.

M3.Gantry feeding equipment for cost effectiveness.

M4.Reasonable excrete disposal equipment to clean the cage completely.

M5.Multiple environmental control design and triple warning system.

M6.to protect your property.

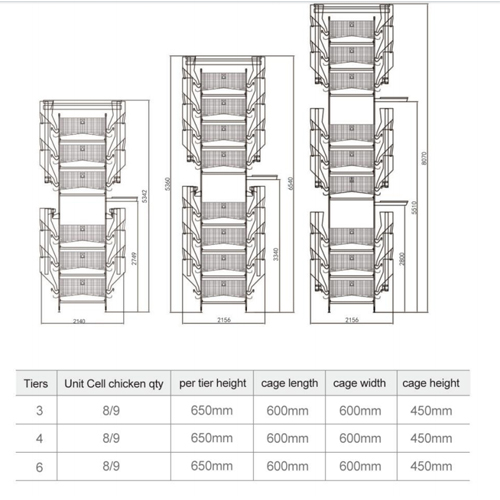

Layer cages H-TYPE

H type layer cage rearing system

LC1.high density raise economical use of land, save about 70% than A type.

LC2.save space,one square meter can raise 62 chickens.use transportation belt to clean manure also make it to granularity,reduce environment pollution.

LC3.the most ideal way to raise environmental protection egg.The chicken cage is a large laminated cabinet frame.

LC4.cage with the size of 1.2×1.2m.

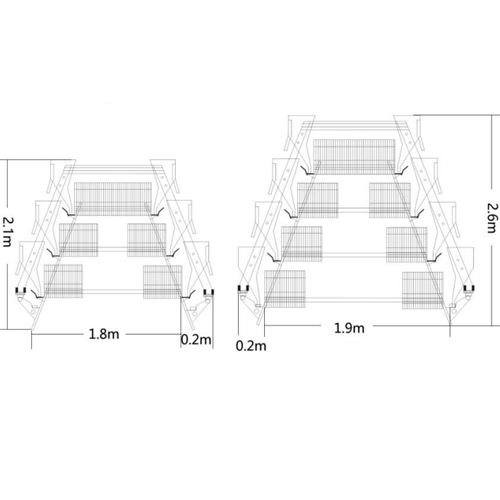

Layer cages A-TYPE

L1.Every nets and bottom nets are encryption, can effectively prevent the peck plume pecked the anus.

L2.Unique door, door reinforcement design space increases, it will be convenient for the chicken exercise and activity.

L3.High density raise economical use of land, which is beneficial to reduce the epidemic disease incidence rate.

B1.high density raise economical use of land, save about 70% than A type.

B2.save space,one square meter can raise 62 chickens.

B3.use transportation belt to clean manure also make it to granularity,reduce environment pollution.

B4.the most ideal way to raise environmental protection egg.

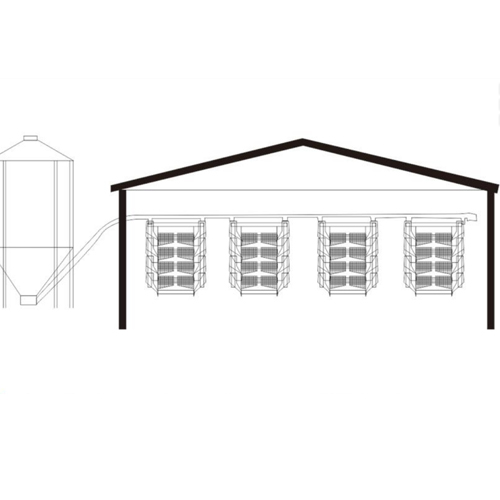

Ground System Equipment

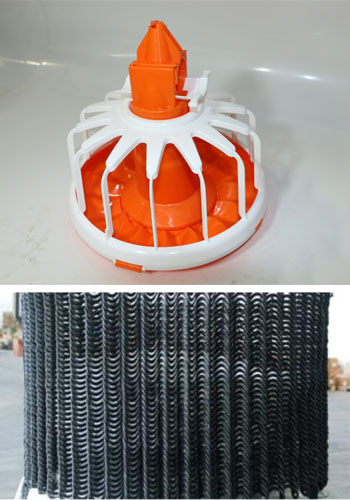

Automatic Pan feeding system

Pan feeding system consists of a driving device, a hopper, a conveying pipe,an auger, trays, a suspension lifting device, an anti perching device and a feed sensor. The main function of the system is to convey the feed in the hopper into each tray to ensure the eating of the meat chickens and automatically control the conveying opening/closing of the motor by the material level sensor o achieve the aim of automatic feeding.

Automatic nipple drinking system

PP outside and stainless steel inside Water-saving,reduce illness,labor-saving

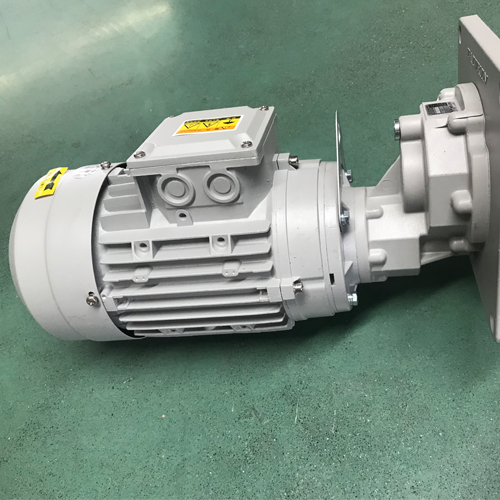

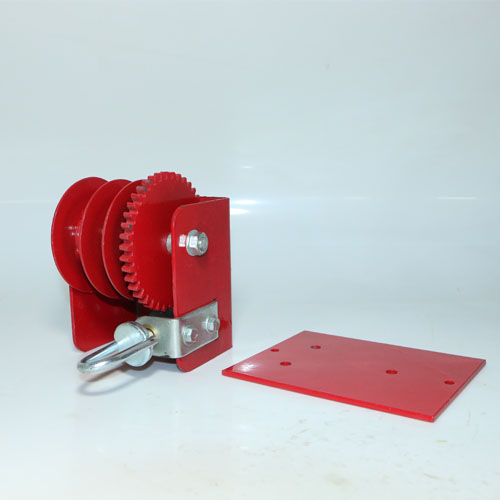

Hanging system includewinch,pulley,Shook, steel wireand so on.Max lifting weight:680kg

Made up of best plastic, so it’s lightin weight and long life span inusageSave water, convenient todismantle and use.

stabilize the water level and enables enough water supplies;indicatingtube is high in transparence andtenacity, so it’ s easy to observethe water levelreasonable designmakes it much easier to dissemble

Dosatron medicator imported fromFrance,ISO9001-2000 certificate,don’ t need electric, drive by waterpress.

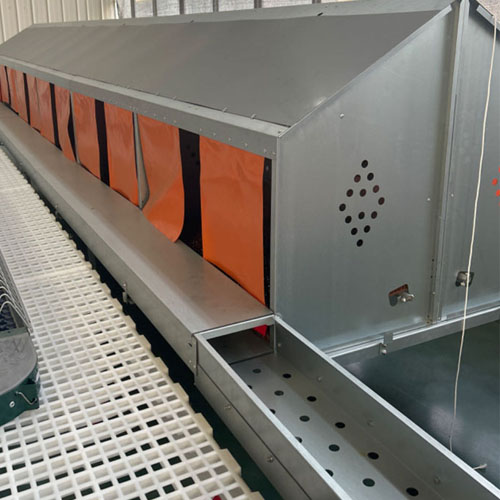

Breeder System

S1.every pan fill feed at same time in order to make surechicken could eat same food at same time, eliminatechicken stress reaction,grow balanced,high laying rate.

S2.use chain plastic disc delivery feed,reduce feed broken;close delivery material decrease noise and pipe abrasion.

S3.softness link can be recycled supply feed,easy to install.

Nest Box

MN1.Short egg roll distance: good egg quality, reduce the percentage of broken eggs and removed eggs.

MN2.Gentle slope at the back end of the egg laying box: the egg rolls gently onto the egg conveyor belt.

MN3.A separate egg box floor allows all eggs left in the egg box to roll onto the egg conveyor until the egg box is closed.

MN4.There is no risk of the hens pecking behind them, since they sit with their chests out of the egg-box during laying;

MN5.Keep the egg box clean throughout the production period, reduce the rate of dirty eggs.

MN6.The exquisite structure allows for effective mite control, with no gaps or crevices to store dirt.

Fan And Cooling Pad

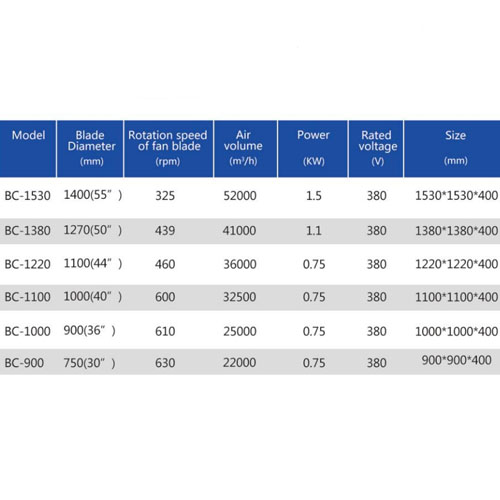

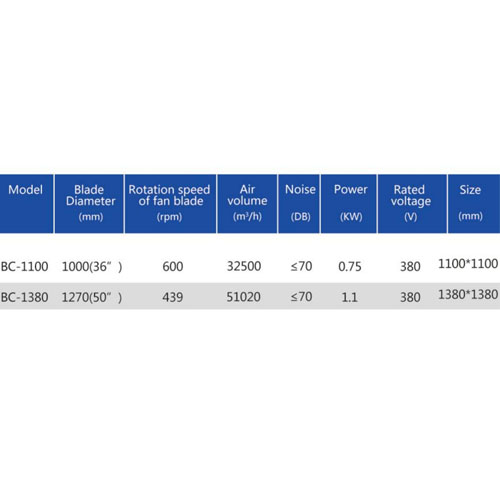

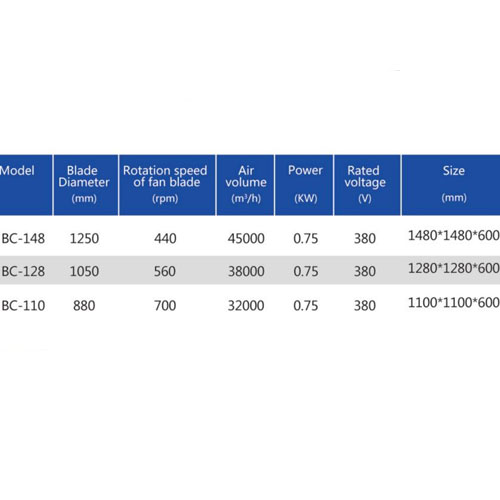

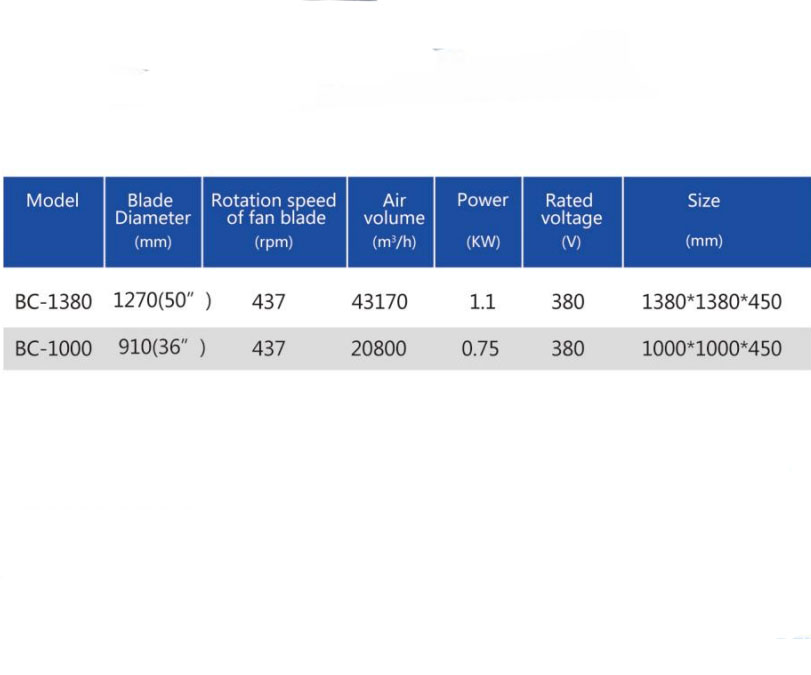

FAN

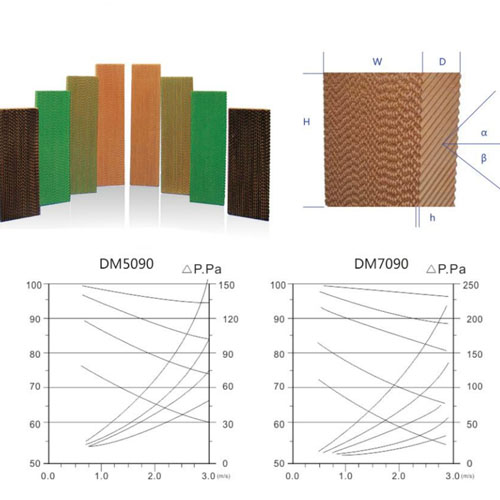

Evaporative Cooling Pad

E1.two model:7090 and 5090.

E2.four color can be choose:brown,green,green&brown,black.

E3.three frame material:aluminum alloy,stainless steel and hot galvanized steel.

E4.strictly according standard to produce,85 pieces 600mm width paper;adopt imported kraft paper,weight is 105g/m3,tension stress:70N,thickness 0.18-0.20mm suction height 45mm/10min,moisture 5%-8%,wet strength:18N

Silo And Other

Silo

Detailed information:

S1. Silo body is made of 275g/m2 hot galvanized pane(two sides),There is a hole on the hypo-cone for inspecting the feed level.

S2.We have different kinds of silo for different demands

S3.All are high intensive,anti-corrosive,easy-installing and have years longevity.

Silo weighing system

Intelligent recording system makes perfusion feeding more convenient.

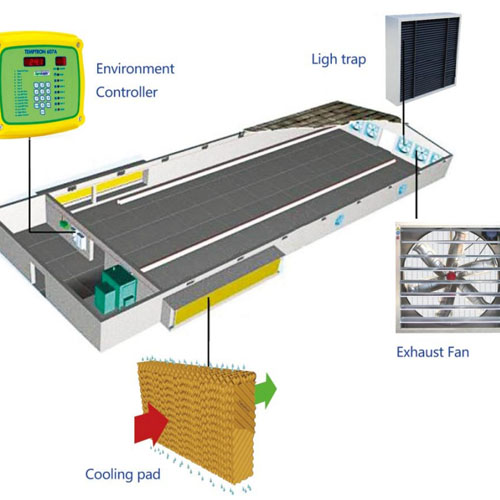

Environment Controller

EC1.environment control system has chicken grow temperature curve,minimum air volume curve, light curve, automatic control crosswise and length ways ventilate.

EC2.control exhaust fan, heater stove,curtain,cooling pad, light system

and feeding line.

EC3.Can through the mobile phone to realize remote real-time monitoring

and mangement.

Chicken Plastic Slat Floor

C1.size:1.2*0.5m

C2.100% raw plastic material lead to following advantage high tensity,ageing resistant.anti-corrosion ,strong capacity,easy to clean&fix,long service life.

C3.reasonable leak hole,avoid hurt chicken feet.

C4.easy to install,smooth surface.

Chicken cage cleaning machine

CC1.The main machine power is 15kw, the swing arm has 2 nozzles and 3 ground nozzles.

CC2.The power of the main machine is 22kw, the swing arm has 4 nozzles, and the ground spray has 4 nozzles.

CC3.The main machine power is 30kw, the swing arm has 6 nozzles and 4 ground nozzles.